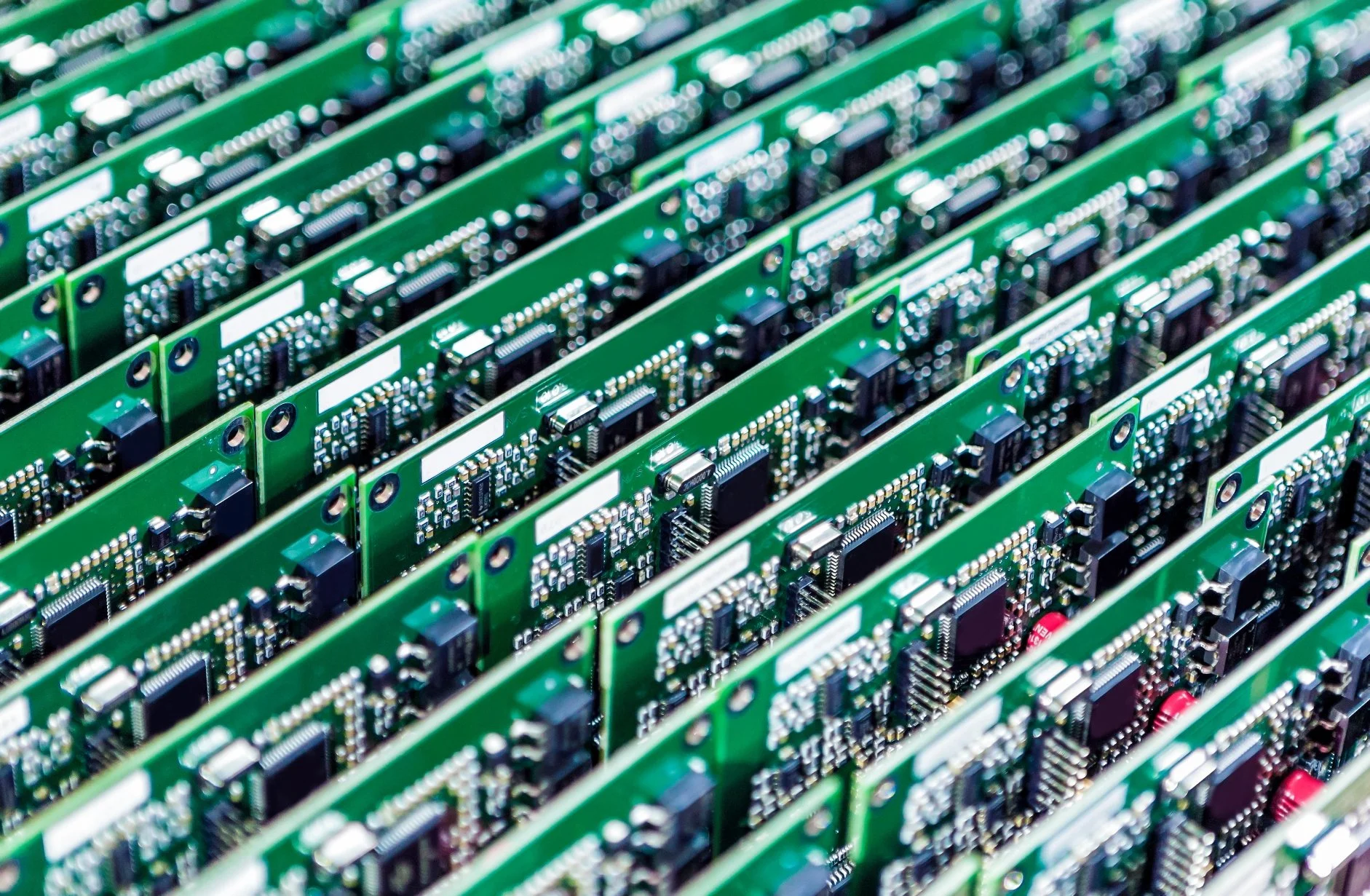

PCB Assembly

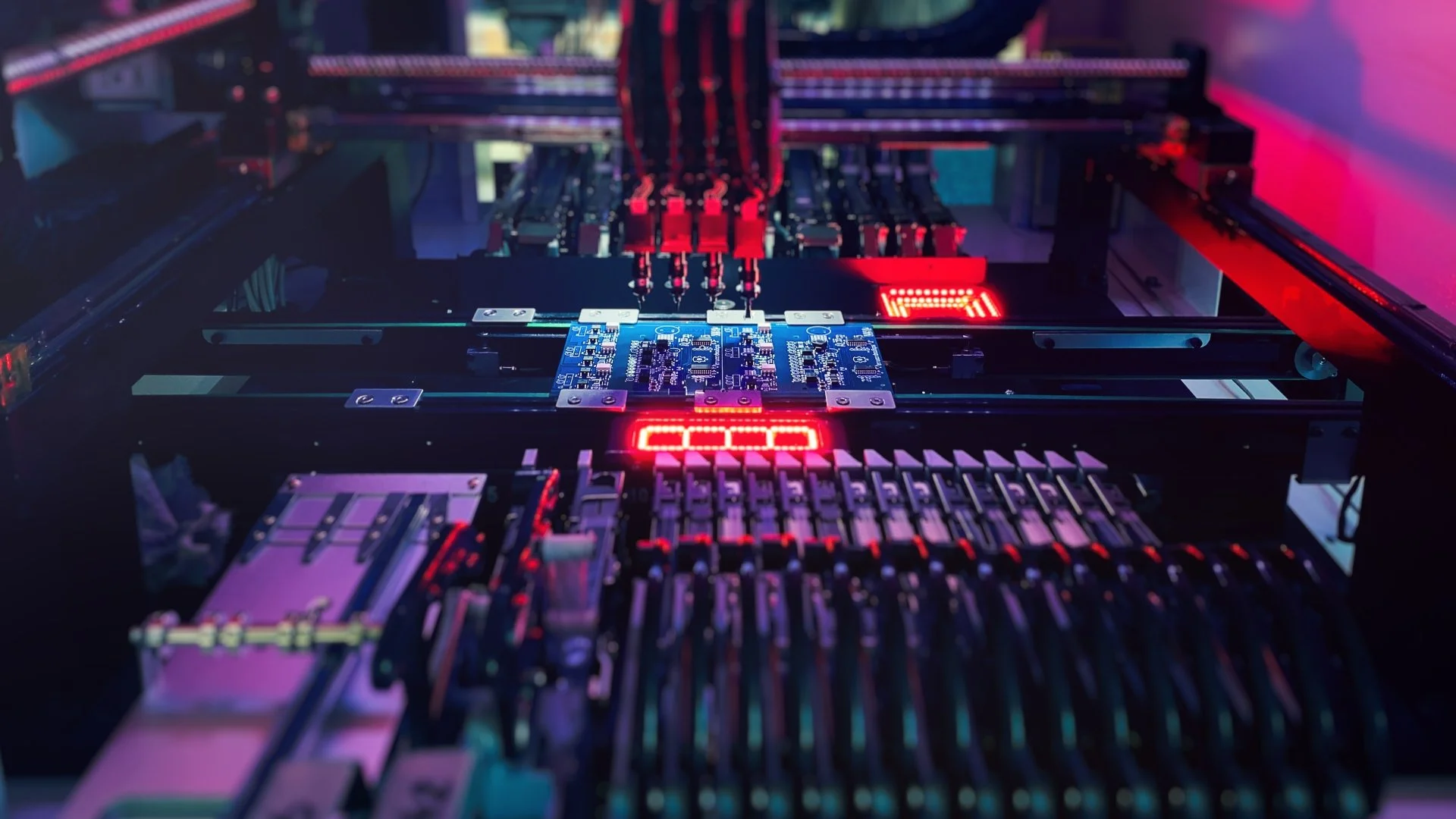

Quantum Tech Services provides advanced PCB assembly (PCBA) solutions engineered to support a wide range of electronic manufacturing requirements.

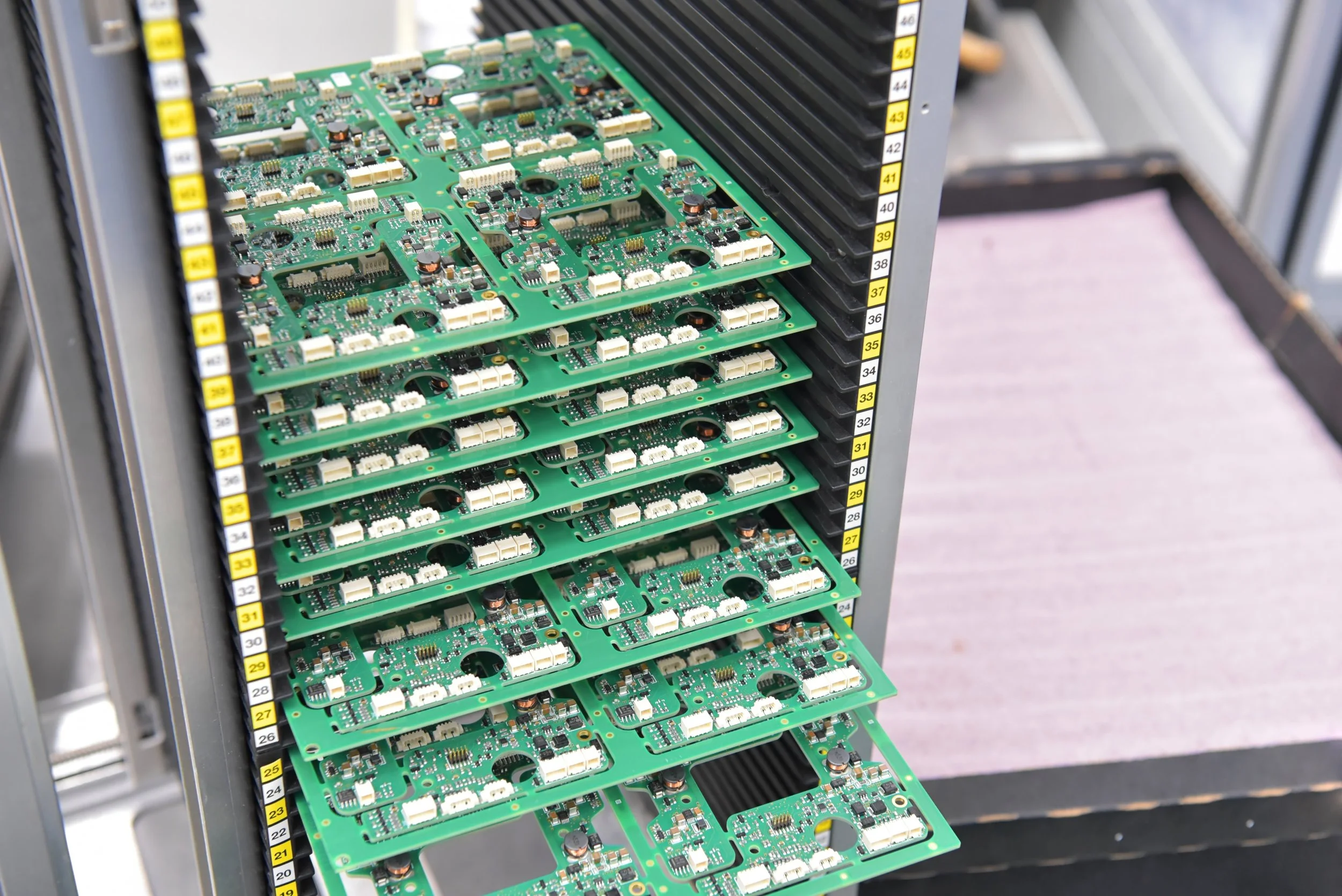

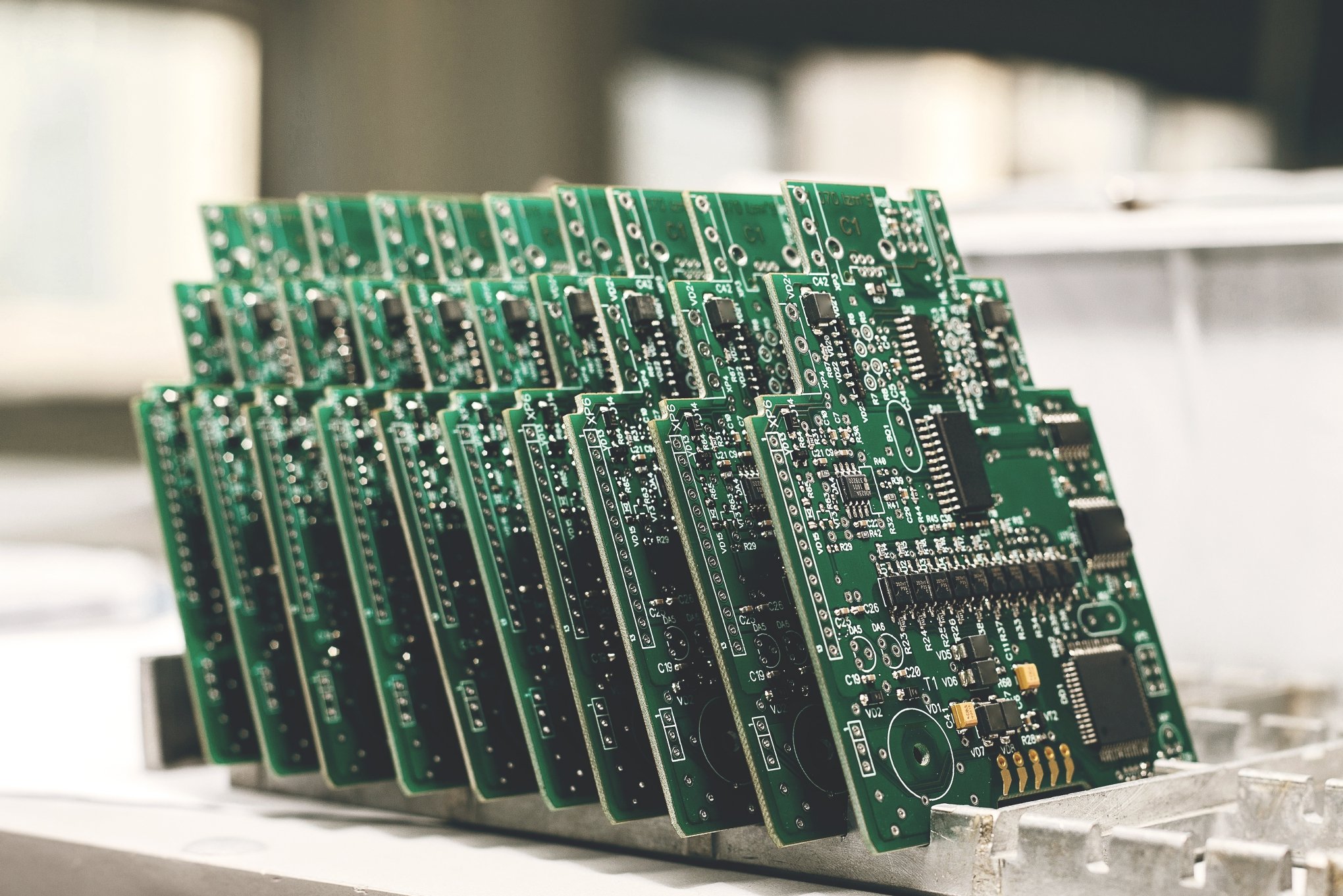

We support single-layer and multi-layer PCBs, including flex, semi-rigid, and aluminum core constructions, across varying material thicknesses and board dimensions. Our manufacturing processes are optimized to accommodate both low-volume prototypes and high-mix, high-reliability production runs.

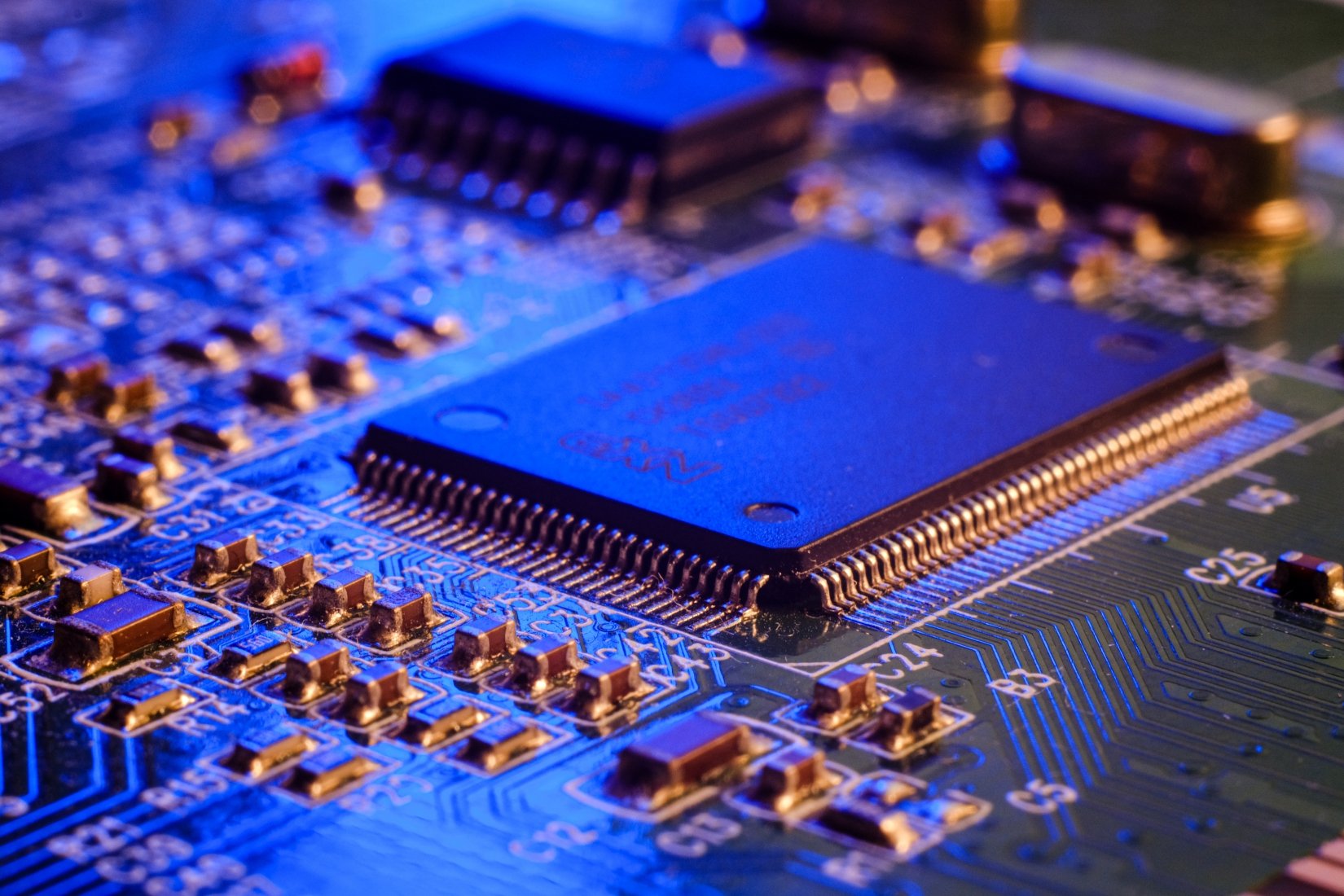

Assembly capabilities include both Surface Mount Technology (SMT) and Through-Hole Technology (THT), with component placement ranging from ultra-fine 0201 chip components to large-form-factor through-hole power devices. All manufacturing activities are performed in compliance with ISO 9001-certified quality management systems, ensuring controlled processes, traceability, and repeatability throughout production.

Value-added services include full batch and component traceability, PCBA cleaning, conformal coating application, and in-circuit, functional, and final product testing. These services ensure electrical integrity, environmental protection, and long-term performance of each assembly prior to shipment.